Compression and tensile forces, static and dynamic Nominal force range: 200 N to 630 kN Accuracy class: 0.02 to 0.05 Fatigue endurance limit: >100 million load cycles Mounting: Flange or threaded IP rating: up to IP68

More

Optimised for dynamic compression and tensile forces Integrated MEMS accelerometers Nominal force range: 1.25 kN to 2.5 MN Accuracy class: 0.03 - 0.06 Fatigue endurance limit: >100 million load cycles Mounting: threaded or flange

More

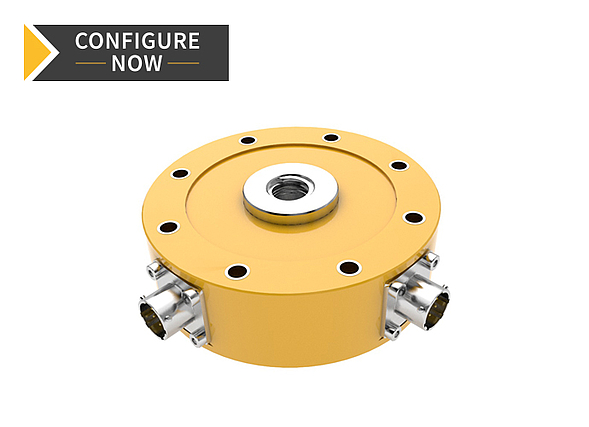

Compression and tensile forces, static and dynamic Nominal force range: 25 kN to 10 MN Accuracy class: 0.05 Fatigue endurance limit: >100 million load cycles Mounting: flange IP rating: up to IP68

More

Compression and tensile forces for low rated forces Nominal force range: 5 N to 100 N Accuracy class: 0.03 Overload protection: 10-fold Mounting: fast and easy from one side

More

Optimised for dynamic compression and tensile forces Nominal force range: 20 kN to 500 kN Accuracy class: 0.2 to 0.3 Fatigue endurance limit: >100 million load cycles Mounting: Internal threads Very compact & robust design

More

Best-in-class force transfer standard for compression forces GTM accuracy class VN: 40 - 100% ISO376 precision class 00: 20% - 100% Nominal force range: 10 kN to 5000 kN Hermetically sealed, low weight and easy adaptation

More

Best-in-class force transfer standard for compression and tensile forces ISO376 precision class: 00 and 0.5 between 10% and 100% Nominal force range: 5 N to 1000 kN Hermetically sealed, low weight and easy adaptation Standardized connection dimensions

More

Best-in-class transfer build-up system for compression forces Engineered to order for your application Nominal force range: up to 50 MN ISO376 precision class: 00 Modular design with adapted measuring ranges

More

Force transfer standard for static compression & tensile forces ISO376 precision class 0.5: between 5% and 100% ISO376 precision class 00: between 20% and 100% Nominal force range: 2.5 kN to 1.2 MN Low weight

More

Best-in-class force transfer standard for high static compression forces ISO376 precision class: 0.5 from 20% – 100% Nominal force range: 1 MN to 30 MN Especially tolerant in case of overload Standard-compliant accessories

More

Calibration in the case of static pulling forces ISO376 precision class 0.5: between 20% and 100% Nominal force range: 200 kN to 10 MN High precision Low weight

More

Version acc. to EN12390, including accessories Nominal force range EN12390: 2 MN Nominal force range: up to 3 MN Extremely compact and lightweight design Other versions departing from standard

More