The ideal Multi-Component Sensor for Standardized Industrial Measuring Tasks with Minimal Signal Cross-Talk

The multi-axis transducers of the LVS series feature impressive dynamic fatigue strength limits on all channels. In many industrial applications, the defined basic loads allow easy selection of the right size and parameter spread with accuracy class 0.1 on each channel. LVS series multi-axis sensors are ideal for precise and reliable execution of standardized industrial measurements. The transducer versions with three or six components are available on short notice.

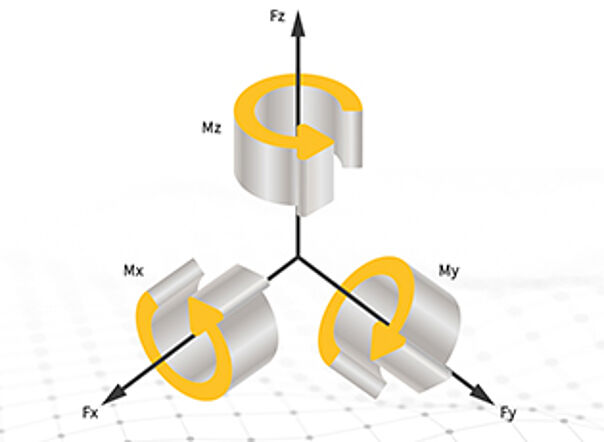

Due to high-precision manufacturing as a monolithic part, manual finishing and calibration, the LVS multi-component transducer features a custom 6x6 sensitivity matrix for high-precision measurements with minimal signal cross-talk. The LVS series of multi-component sensors measures three or six combined forces and torques in three axes (x, y, z).

Depending on the application to be used in, the precision measuring amplifiers of the LT-Digitizer or MCMpro series with integratedcompensation matrix adjustment are ideal forthe entire measuring chain. GTM gives the user everything from a single source – from multi-axis transducers to precision measuring amplifiers.

Preferred uses of the LVS multi-axis sensor series include static and dynamic measurements for testing components in automotive, aviation and general machine engineering. Take advantage of more than 25 years of experience in the field of multi-axis transducers.