Outstanding DAQ performance for test bench applications and industrial quality and process control at the highest level - with sensor-near EtherCAT® interface and all from a single source: The new innovative, ultra-compact, single-channel in-line measuring amplifier ILA perfects GTM's precision force measurement chain.

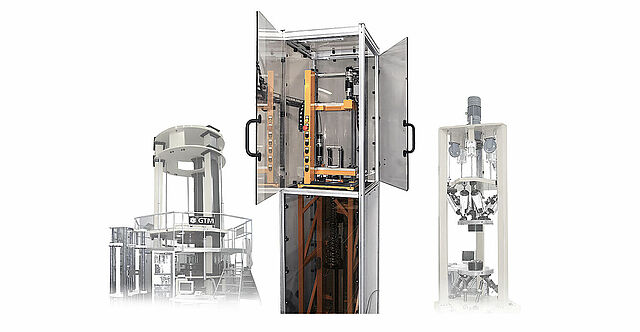

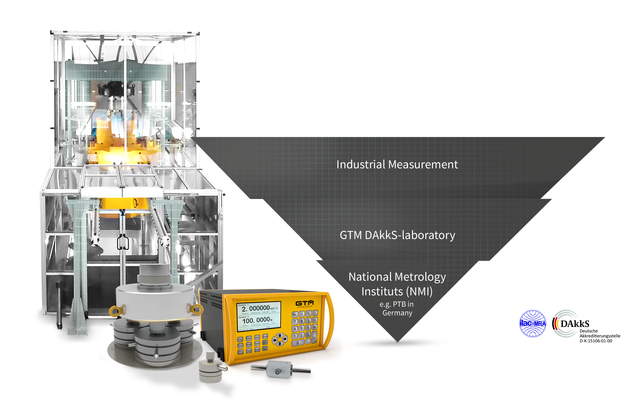

We supply our metrological standard machines to National Metrology Institutes (NMIs), calibration laboratories and to manufacturers of force and torque transducers. GTM can supply turnkey metrological standard machines of the highest standard worldwide, with a proven track record of extreme reliability and success. The complete metrological solution from a single source - from sensor to standard machines

The absolute pursuit of precision and innovation drives us. In the beginning there was one customer, today there are thousands worldwide. Founded in 1988, we set standards in our special field, the measurement of forces and moments, from the very beginning. In our standard products, special designs and services, we always work at the highest level. This is how we set the standards when it comes to measurement technology. We make the world a better place because we are instrumental in ensuring that a NEWTON is a NEWTON everywhere in the world.