10/04/2022

#World's first in multi-component calibration by GTM

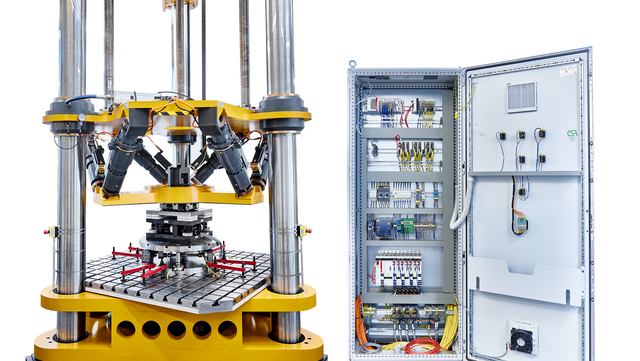

With the new development of a standard machine for multi-axis transducers, we at GTM have set another milestone in metrology. The groundbreaking: When calibrating multi-axis transducers, the various force vectors are measured simultaneously and fully automatically - a world first.

When it comes to measuring forces along several vector axes, possibly simultaneously, so-called multi-axis transducers are used. Examples of applications for these high-precision sensors can be found in the aerospace industry, in wind energy technology or on vehicle test benches. To ensure precision at all times, multi-axis transducers must be calibrated at regular intervals - a service that has also been part of our comprehensive portfolio since 2005.

Faster results through automation

Depending on the application, already up to three of the different vector axes (x, y, z) are measured one after the other during calibration with the existing method. Until now, the calibration machine was operated manually, which was time-consuming. With the newly developed multi-axis calibration machine, on the other hand, it is now possible to measure forces and torques in all vector axes simultaneously, and this completely automatically. Thereby, even gravity can be simulated well in all axes.

This gives GTM customers who take advantage of the calibration services an enormous time advantage, since their multi-axis transducers to be calibrated are back in operation more quickly than before. Also, the data obtained with the newer method are more meaningful, their information content about the behavior of the calibrated object is much higher. Last but not least, the relative uncertainty of measurement of the new calibration machine is groundbreaking at only 0.1 % compared to the existing calibration machine of 0.5 %.

With many years of experience and a breath of fresh air to the solution

Such a groundbreaking and complex new development always requires a strong team with fresh ideas, but also many years of experience in metrology and an open error culture: This is the only way to find new ways and solutions. As part of the development team, our employees Martin Eller and Martin Urbanski contributed to the success of the new multi-axis standard machine and shared their experiences with us. You can find the interview further down on this page.

With the new multi-axis standard machine, we have further developed a technology with which we intend to further expand our leading position in the field of metrology. Our customers and partners will also benefit noticeably from this advance.

Martin Eller, when did you join GTM and what did you do before?

"I joined GTM in 2018 after completing my mechanical engineering studies. Before that, I did an apprenticeship as an industrial mechanic and gained initial work experience. This meant that when I joined GTM, I had acquired both practical and important theoretical knowledge, which helped me a lot in the implementation of the project.

How did you become the main contact person for the project?

"It was a rather gradual process. Especially at the beginning, a lot of input flowed into the project from my colleagues, who already had many years of experience in metrology. Nevertheless, I was involved from the beginning and often asked for my opinion on various aspects. I am very grateful for this appreciation and the trust placed in me. After about a year, I then became the main contact person for the project.

What did you particularly like about the project?

"It's an incredibly great feeling to have been significantly involved in such a project. After all, with this standard machine we have developed something that is not yet available on the market. It makes one proud to see that all the assumptions and calculations were correct. But with all the work, there was never a shortage of fun. The cooperation with the colleagues, the electrical and software engineers, and the metrologists was always on an equal footing. The team spirit is definitely something I really appreciate at GTM.

Martin Urbanski, what is your situation like? How did you come to GTM and to this project?

"In my case, the path led from training to studies to GTM. I have been with GTM since 2019 and have been involved with the control and operating software, the GTM WebForceManager, of the already existing measuring equipment almost from the beginning. With the knowledge gained from this, I then developed both a software concept and implemented the control for the multi-axis standard machine.

What about your learnings and a personal statement about the project?

"As Martin Eller has already said, it makes you incredibly proud when you look back on what we achieved. For me, for example, the cinematic calculations of a hexapod and the realization of a force control system with six degrees of freedom were completely new territory. It's great to see that all our efforts have led to such a great result. Even if, unfortunately, it is not immediately apparent how much sweat and work actually went into it. Above all, however, it was the super cooperation with colleagues from a wide range of disciplines that led to the success of this standard machine. I am therefore already looking forward to the next projects that lie ahead of us!