If for example an industrial application in medical or engineering or robotics requires simultaneous measurement of forces or torques along multiple vector axes, a so-called multi-axis-transducer is recommended. A multi-axis-transducer, also known as a multi-component transducer or sensor, measures forces and moments that occur in more than one spacial axis – e.g. measurement in the x and y axis – and is also extremely compact.

GTM is the top choice for reliable and innovative industrial multi-axis measuring technology: standardized or application-optimized multi-axis transducers, multi-axis measuring platforms, tire uniformity and torsion testing machines, or wheel force sensors for the automotive industry. GTM multi-axis sensors are often ideal for use in high-end multi-axial test benches, for example for function tests, or component and structural testing. In 2005, our calibration lab was the first in the world to be accredited for calibration of multi-component transducers. Since then, we have been working endlessly to research and develop new multi-axis measuring systems and to optimize existing force transducers, as well as to create custom high-precision multi-component measuring platforms.

Depending on the series, both multi-axis transducers and multi-axis systems are custom designed and manufactured by GTM on the basis of your requirements. Our highly competent team of developers will provide short-term support to help you achieve a fast and flexible specification. On the basis of the Engineered-to-Order principle we jointly develop the perfect measuring solution for you, no matter whether you require a monolithic compact multi-component transducer or multi-component systems.

In accordance with the Engineered-to-Order principle, GTM multi-axis measuring platforms and multi-axis measuring systems are always created with a focus on your specific application. Direct contact with our highly qualified development team is the key to the best solution for your requirement – fast, efficient and focused. This ensures that your investment is designed in perfect harmony with the goal of achieving the optimal technical solution, a long life, and a perfect total cost of ownership for you.

All GTM multi-axis sensors and multi-axis measuring systems feature outstanding precision and minimal margins of error throughout the entire measurement range. GTM also provides you with a custom compensation matrix, which can greatly reduce cross-talk between your measuring signals. The compensation matrix is a basic requirement for assessing and minimizing cross-talk with smart GTM measuring technology. In addition, GTM always uses high-quality connecting cables, exclusively with 6-wire technology.

GTM has been using multi-component technology for more than 25 years, and is constantly developing the technology further. Take advantage of this unique expertise, especially in our Engineered-to-Order solutions, which are custom tailored to your requirements.

All GTM multi-axis solutions are manufactured using very high-quality materials and production processes. Our solutions use either compact monolithic measuring elements or distributed systems with multiple transducers consisting of high-quality mechanical components. This makes it possible to fulfil extreme requirements for sensitivity and precision, and to achieve a long service life of more than 15 years.

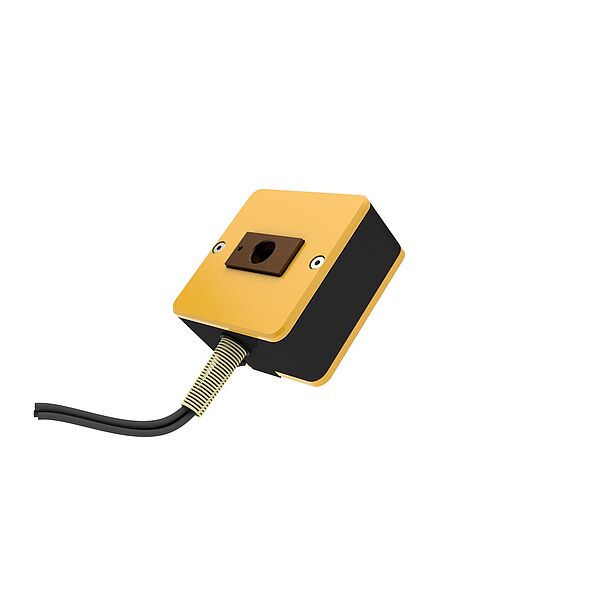

Strain gauge measuring amplifiers of the MCMpro and LT-Digitizer series from GTM are ideally suited for use with our multi-axis transducers and systems. They feature all mathematical functions needed for the special requirements of multi-axis measuring technology, such as processing of the custom compensation matrix for minimizing cross-talk.

All GTM development processes are carried out in Germany. The same applies to customizing and OEM. Our multi-axis transducers, multi-axis measuring platforms and multi-component systems are produced in Germany. That ensures that you have a secure and reliable supply chain – developed and produced in Germany.