Assessment of the effect of rotating forces on mechanical systems is one of the central measuring tasks during technical developments in diverse industries and disciplines. Based on our extensive experience with strain gauge force measurement we have developed high-precision torque transducers for non-rotating torque measurement that are specially optimized for high-end metrological and industrial test bench applications. Our torque transfer standards and torque transfer wrenches are recommended for comparison of National Metrological Institutes (NMI) or for traceability. GTM torque transfer standards are the top choice for factory standards, reference standards, and calibration and traceability of accredited industrial calibration labs to the national standard.

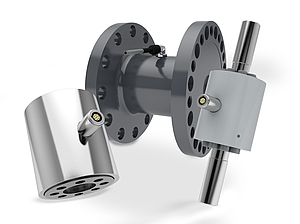

Torque Transducer Series M

- For static and dynamic torques

- Nominal torque range: 2 N·m to 10 kN·m

- Accuracy class: 0.05

- Fatigue endurance limit: >100 million load cycles

- Non-rotating version

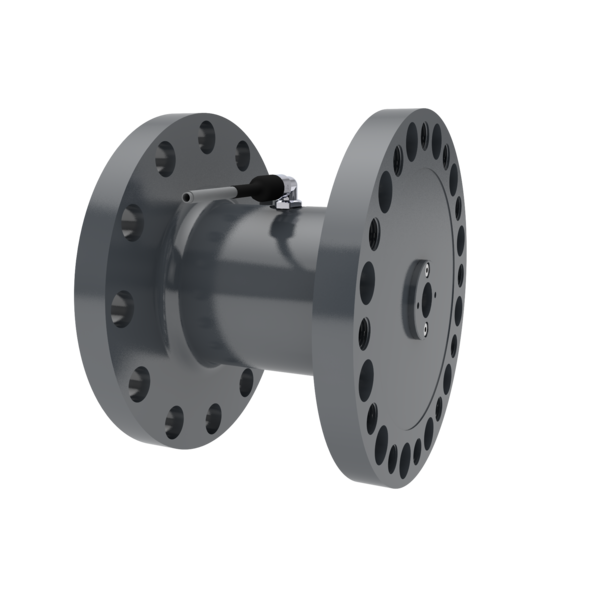

Torque Transducer Series MF

- For static and dynamic torques

- Nominal torque range: 100 N·m to 150 kN·m

- Accuracy class: 0.05

- Fatigue endurance limit: >100 million load cycles

- Non-rotating version

Torque Transfer Standard Series Dm-TN

- For calibration of measuring instruments

- Pure static torque measurement

- GTM accuracy class VN: 40 - 100%

- DIN 51309 accuracy class 0.05: 20 - 100%

- Nominal torque range: 1 N m to 20 kN m

Torque Transfer Wrench Series Dm-TS

- Measuring of static torques with transverse force

- Precise calibration of torque calibration equipment

- DKD-R-3-7 classes: 0.1 and 0.2

- Nominal torque range: 2 N·m to 3 kN·m

Why You Should Choose GTM Torque Transducers and Transfer Standards – Your Customer Benefits!

We support you in finding a solution for your torque measurement task with a huge diversity of functions that are custom tailored to the requirements of your torque sensor application. Configure your custom torque transducer on the basis of GTM’s diverse options. We provide the support to help you create your solution! Our experts will assist you first-hand with planning, engineering, installation and commissioning – always with the goal of providing a suitable and efficient torque transducer solution for your torque measurement application, with no compromises in quality, performance and precision.

Designed for Precision

High-Precision and Reliable Measurements

In addition to outstanding precision and minimal margins of error throughout the entire measuring range, GTM torque transducers also exhibit extremely low sensitivity to parasitic influences. This means that transverse forces, bending moments and temperature fluctuations do not have a chance – optimal conditions for the most precise torque measurements conceivable. GTM uses high-quality connecting cables for all torque transducers and measuring leads – exclusively 6-conductor versions – to ensure precise transmission of your precise torque measurements.

Designed For a Long Life

Maximum Investment Security

GTM torque transducers give you excellent investment security, because they are designed for a long life. That is why the robust and durable GTM force transducers can achieve a fatigue endurance limit of more than 100 million load cycles (depending on the series ≤80% or ≤100% Mnom). Depending on the series, our torque transducers can also withstand torques up to 300 % of the rated torque without breaking, and up to 150 % of the rated torque without effects on the measurement and zero point. GTM torque transducers are manufactured using very high-quality materials and production processes.

Designed for Metrology & Traceability

Torque Transfer Standards and Reference Transducers

Best-in-class torque transfer standards from GTM are a worldwide synonym for the metrological traceability of moments. That is why they have become standard at many National Metrological Institutes(NMI) – in use for more than 20 years, always precise and continuously under further development. The Dm-TN series even exceeds the DIN 51309 standard many times over and therefore measures at the physical limit. To supplement the torque transfer standards, GTM uses only accessories of the highest quality. This applies both to strain gauge measuring amplifiers and double-shielded measuring cables, as well as standard-compliant mounting components.

Designed for Mechanical Integration

Very Easy Mounting and Optimal Adaptation

GTM torque transducers are designed for easy mounting and optimal adaptation to allow integration in existing and new constructions. We offer numerous very high-quality mechanical adaptations for the different torque transducers.

Your Best-In-Class Partner

Development and Production in Germany and Europe

All GTM development processes are carried out in Germany. The same applies to customizing and OEM. All of our torque transducers and torque transfer standards are produced in Germany and Europe. That ensures that you always have a secure and reliable supply chain – developed and produced in Europe.